08/08/2024

Geothermal Brine to Battery-Grade Lithium: EnBW and LevertonHELM’s Collaboration

Lithium’s role in the quest to facilitate the transition to zero-emission industry

With no surprise, after Europe’s quest to replace fossil fuels and turn towards clean energy, lithium (Li) has been classified as a key component, making it to the short list of EU’s highly significant critical raw materials. With the transition to zero-emission vehicles, carmakers, as the most consuming industrial sector, will need ever more Li for batteries.

Renowned for its policy background, the EU decisional institutions adopted the Critical Raw Materials Act (CRMA) in record time. This accelerated adoption procedure shows nothing but the need for action, which reflects Europe’s urge to secure a sustainable supply of critical raw materials (CRMs). The CRMA sets specific targets to strengthen the EU’s capacities along the different stages of the value chain, ensuring that by 2030:

- the EU extraction capacity covers at least 10 % of the EU’s annual consumption of strategic raw materials.

- the EU processing capacity covers at least 40 % of the EU’s annual consumption of strategic raw materials.

- the EU recycling capacity covers at least 25 % of the EU’s annual consumption of strategic raw materials.

- no more than 65 % of EU’s annual consumption from a single third country.

Research and industry – hand-in-hand to demonstrate sustainable production of cathode materials for batteries from geothermal resources

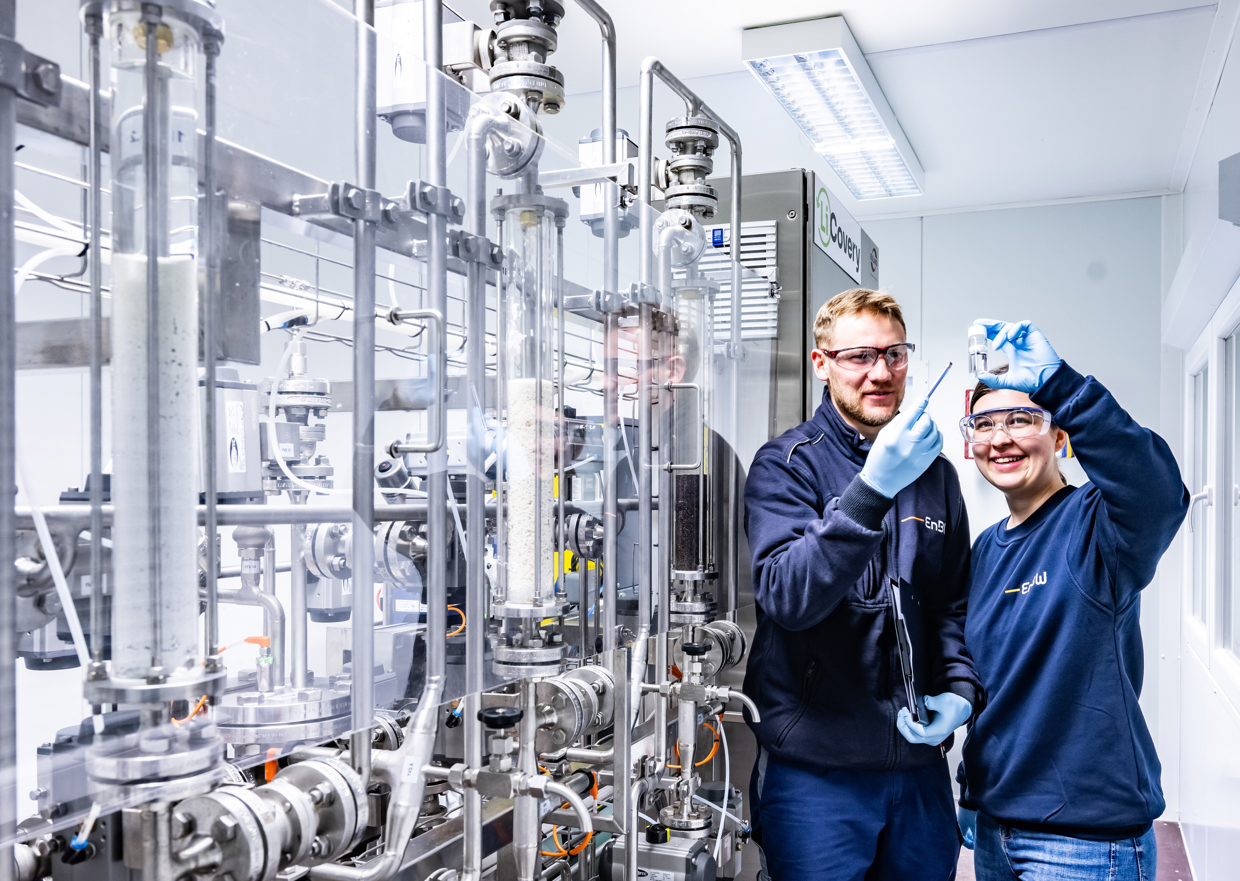

Both EnBW and LevertonHELM are key partners in the LiCORNE project. EnBW, as one of the largest energy supply companies in Germany and Europe, has the following tasks in the LiCORNE project: 1) to supply geothermal brine feedstock, respectively to conduct develop Li+ desorption technology aiming at min. 90% yield from geothermal and continental brines. LevertonHELM, on the other side, is a Lithium chemicals producer based in the UK, focusing on the manufacturing of a wide range of inorganic Li chemicals. In the framework of LiCORNE, the British company will benchmark and qualify the Li produced by the processes developed in the project, as battery-grade material.

German, respectively British companies have expanded their collaboration beyond the project’s framework, with a joint objective to advance the sustainable production of battery-grade Li carbonate and Li hydroxide – essential materials for electric mobility and energy storage solutions.

In previous articles, EnBW reported high Li concentrations for the geothermal brines in the Upper Rhine Valley (Bruchsal reservoir), ranging from 163 to 190 mg/L (Sanjuan et al., 2016). However, due to the characteristics of the reservoir, featuring highly mineralised brines, the extraction process was hampered by an elevated additional concentration of foreign ions (TDS 130 g/l). According to Laura Herrmann, Project Manager Research and Development at EnBW, the process requires increased selective adsorption technology in line with the exigences of the battery materials producers.

EnBW and LevertonHELM produce Li carbonate for the first time from geothermal brine in Germany

This industrial collaboration has resulted in a remarkable purity of 99.5% for lithium carbonate, demonstrating great potential for further scale-up to meet the EU’s demand for lithium.

Using direct Li extraction by adsorption (A-DLE), the process coordinated by the industrial partnership led to a remarkable purity of 99.5 % for Li carbonate. This successful initial trial holds promise for future upscale, potentially meeting the EU’s demand for Li.

Curious to learn more about the Direct Lithium Extraction technologies developed and tested in LiCORNE?

Register to the Symposium on Direct Lithium Extraction

© visual:EnBW